How it works

GF2™Comprehensive Fuel

Enhancer is a combustion catalyst that gives

your engine greater fuel efficiency.

GF2™ decreases combustible

carbon residue by providing a more complete

burn. More efficient combustion yields to

more useful power per gallon of fuel.

GF2™is the ONLY fuel

treatment in the world that reduces soot and

smoke and other harmful emissions a

guaranteed 40%, and in many cases much

higher.

GF2™reduces the harmful

emissions that damage the environment.

Major Uses

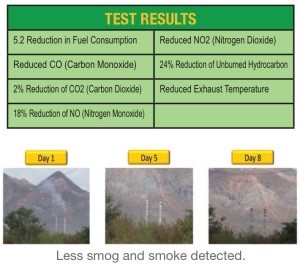

SEE some

Pictures of

What it does

For use in all gasoline and

diesel engines, and both two and four cycle

engines including:

• Cars • Pickups • Heavy

Trucks • Buses • Yard Equipment •

Motorcycles • Snowmobiles • ATVs • Boats •

RVs • Generators • Farm Equipment •

Construction Equipment

FAQ's

Why is GF2™Fuel Enhancer

better than other fuel additives on the

market?

It’s the only one of it’s kind in the world

that has been formulated with a lubricant,

water emulsifier, polymerization retardant,

oxidation stabilizer and corrosion

inhibitors. It is highly concentrated fuel

additive. 1 ounce will treat 80 gallons of

fuel.

What exactly is in

GF2™Fuel Enhancer?

Combustion Catalyst (Complex

Organometallic compounds) , Lubrication,

Water Demulsifier, Polymerization

Retardants, Oxidation Stabilizers,

Detergents and Corrosion Inhibitors.

What does an

Organometallic compound do?

It lowers the initial ignition point of

the fuel in the cylinder allowing more time

for the fuel closest to the piston to burn

more completely. Your engine only has a

limited amount of time to burn all of the

fuel in the combustion chamber before it is

swept out to the exhaust. Without GF2™, fuel

is ignited from only one point in the

chamber. The flame burns from the top down

to the piston head. GF2™contains

Organometallic compounds that act as flame

initiators. Because of this, the flame in

your engine’s combustion chamber isn’t

propagating only from top to bottom. It’s

also propagating from all of the GF2™

molecules in the fuel. More of the fuel in

the chamber will be burned on each stroke

and less will be wasted in the exhaust.

This also allows more of the

BTU’s in the fuel to be released and used in

the form of energy to deliver more power to

the transmission and provide better overall

fuel economy.

How does GF2™Fuel

Enhancer affect the Cetane or Octane value

of the fuel?

The cetane value of Diesel is greatly

enhanced by using GF2 allowing for the

diesel and all heavy fuels such as bunker

fuel or No 6 fuel to burn more efficiently

and cleaner obtaining close to the full

Cetane value of the fuel. In gasoline

engines you can use the lowest octane fuel

with GF2™ to achieve the performance of a

higher Octane fuel. This is a real money

saver for everyone.

Does GF2™Fuel Enhancer

increase the BTU’s in the fuel?

BTU’s are not increased in fuel with the use

of GF2™ Fuel Enhancer. GF2™ is able to

release more of the available BTU’s that

already exist in your fuel. Most engines do

not burn all the fuel available in the

cylinder and therefore do not utilize all

the BTU’s available. Unburnt fuel is

expelled into the exhaust system creating

smoke and pollution in the atmosphere. This

unburnt fuel that is expelled in the exhaust

creates the need for catalytic convertors in

smaller vehicles and Regen systems in larger

vehicles to burn off the unused fuel to

reduce pollution. If the engine can burn

more of the available BTU’s in the fuel then

there is less waste, more power and more

economy and less need for DEF additive in

Regen systems and less need for catalytic

convertors to burn off unused fuel in the

exhaust system.

BTU is a British thermal

unit which measures the amount of energy in

a particular fuel. It is a similar measure

to that of a calorie.

For example: Regular unleaded gasoline

contains 114,100 BTU’s. No 2 Diesel contains

129,500 BTU’s. Liquefied Natural gas (LNG)

contains 75,000, Liquefied Petroleum Gas

(LPG or Propane) contains 84,300, Bio Diesel

contains 118,300.

How does BTU’s relate to

horsepower and fuel economy?

The more of the available BTU’s the engine

uses the more efficient it is. The price of

the fuel must be taken into consideration

that the application it is going to be used

in. For example a large earth moving machine

in a mine will be more efficient using No 2

Diesel with 129,500 BTU’s as it has more

BTU’s per pound of fuel than if the same

machine was using LNG which has 75,000 BTU’s.

It would take 55,500 more BTU’s of LNG to

create the same power of No 2 diesel. This

would mean using larger tanks to contain the

fuel and a larger engine (meaning larger

cylinders and pistons, valve openings etc.)

capable of creating the power necessary to

achieve the same results as the diesel

engine can achieve.

Why does GF2™Fuel

Enhancer contain a lubricant?

Yes, On road diesel fuels today are almost

completely sulfur free. On road gasoline’s

are almost completely lead free. Sulfur and

Lead are natural lubricants. Today’s high

performance engines are subject to much more

wear and breakdown when not lubricated

properly especially in the fuel injectors

and valve systems. GF2™ lubricates the upper

cylinders, valve system and the entire fuel

system minimizing breakdowns and ensuring

long component life.

Why does GF2™ Fuel

Enhancer contain a Water Demulsifier?

All fuels contain some degree of water.

Water is naturally in the atmosphere and

with each 24 hour period of day (warmer) and

night (cooler) condensation is formed inside

fuel tanks and fuel lines including engines.

Water in fuel makes it less efficient in the

engine and also causes acids which are

harmful to the engine and exhaust system.

GF2™separates water from the fuel allowing

the fuel going into the engine to burn more

completely. In this article by American

Filtration and Separations Society, One of

the most commonly thought of sources of

water contamination is through condensation

of atmospheric moisture to form liquid

water. A research study shows that an empty

200 gallon fuel tank could contain a maximum

amount of 22.8 grams of water vapor at 86ºF,

and 12.92 grams at 50ºF[1]. These values do

not account for all of the water observed.

Condensation is only one of the many ways in

which water can contaminate fuel tanks. Fuel

travels through several intermediate

facilities prior to reaching the end user.

It travels from refineries, is pumped

through pipelines, is shipped via truck and

is stored in tank farms before reaching the

fuel stations. http://www.afssociety.org/automotive/93-water-contamination-in-fuel-cause-and-effect

Why does GF2™Fuel

Enhancer have a Polymerization Retardant in

it?

Fuel naturally begins to breakdown soon

after it is refined. Eventually over time it

returns to its natural state as crude oil.

This polymerization process starts to form

submicron-sized particles. As the process

continues, particles become larger and

eventually agglomerate, forming macroscopic

sludge. These particles can score injectors

and eventually plug filters and the very

small openings in the injectors nozzles and

over long periods of time render the fuel

un-pumpable. For example have you ever left

your boat or lawnmower long periods of time

without using it? It becomes very hard to

start it because of this polymerization

process. GF2™ Fuel Enhancer disperses

existing macroscopic sludge and retards

further polymerization, permitting the fuel

to flow and burn more efficiently.

Why does GF2™Fuel

Enhancer have an Oxydation stabilizer?

All fuels are subject to oxidation.

Oxidation creates in-soluble by products

which cause injector deposits. These

deposits can slow response or cause sticking

of moving internal parts and lead to

injector failure. GF2™contains a dispersant

that stabilizes fuels, preventing oxidation.

Why does GF2™Fuel

Enhancer have corrosion inhibitors?

Many parts of an engine are made up of

ferrous metal components, aluminum and

plastics. Many fuels today contain Ethanol

which is alcohol and is highly corrosive to

a variety of components in your fuel lines

and engine. GF2™ contains a corrosion

inhibitor in order to mitigate corrosion in

tanks, engines and fuel lines and a

detergent to help keep engines, fuel lines,

filters, pumps and injectors clean. This

will result in increased efficiency, less

breakdowns and less maintenance for your

equipment.

Is GF2™Fuel Enhancer

beneficial for use in Biodiesel?

GF2™is excellent for use in Biodiesel fuels.

Biodiesel has less BTU’s than No 2 diesel.

Biodiesel is much more prone to higher water

content minimizing it’s effectiveness as

well as being subject to faster fuel

degradation than regular diesel. GF2™ is

ideal for use in this type of fuel, not only

to stabilize it, but also allowing it to

burn more effectively and obtain much more

of the available BTU’s while eliminating the

water content to make it more efficient.

How long has GF2™Fuel

Enhancer been in use?

GF2™has been in use since the early

1990’s. It is proven in all heavy industries

with the emphasis on mining. However we are

currently making it available to the general

public so they can benefit from it amazing

properties.

Can GF2™Fuel Enhancer

reduce pollution?

Yes GF2™is very effective at reducing carbon

and greenhouse gasses up to 70%. It does

this by burning more of the available BTU’s

in the fuel and burning the fuel in the

engine more efficiently; this gives more

horsepower and more fuel economy, which

means you use less fuel to go the same

distance or complete the same amount of

work.

Why was GF2™Fuel Enhancer

not available to the general public?

Heavy industry has been the primary user of

GF2™ .Our goal is to make this fuel additive

available to the general public via network

networking enabling us a simple way to get

the product to small fuel users . We believe

by doing so we will create a greener

environment for our world.

Can GF2™Fuel Enhancer’s

interaction with fuel be explained using a

chemical formula?

The basic principles behind the benefits and

catalytic effects of GF2™ are easy to

understand. Today’s engines leave some

amount of fuel unburned on each piston

stroke. GF2™ makes it easier for your engine

to burn more of the fuel in the cylinder.

Since more of the fuel is being burned, more

power is being generated. Since less of the

fuel is being wasted, you will have fewer

emissions. Chemistry An engine converts fuel

into energy by the following chemical

processes: CxHy + O2 → ( CO2 + H2O ) + ( CO

+ HC + C ) + ΔH

The ΔH is known in chemistry

as enthalpy and represents the energy

created from the thermodynamic process

taking place inside an engine. The CxHy

represents the fuel, for example gasoline is

C8H18 and diesel is C12H26. The CO2, H2O,

CO, HC, and C on the right side of the arrow

represent products that are released in the

engine exhaust.

There are no exothermic

(i.e. energy producing) reactions that could

yield more energy out of the CO2 or H2O, so

we’ve grouped those components together in

the equation above. However, there are

exothermic reactions that can extract

additional energy from the second group: the

CO, HC, and C.

When GF2™ is introduced into

the engine, it acts as a catalyst and lowers

the activation energy needed to further

break down the unburned products in the

above reactions. Specifically, when GF2™ is

used the following additional chemical

processes take place in the engine:

CO + O2 → CO2 + ΔH HC + O2 →

CO2 + H2O + ΔH C + O2 → CO2 + ΔH The ΔH’s in

the three above equations are how GF2™

increases your engine’s output. These ΔH’s

add to the ΔH produced by the engine’s

standard process to deliver more output

energy from the engine. This extra energy

can be used to either increase engine output

power (if the amount of fuel input is kept

constant) or reduce the engine’s fuel intake

(if the amount of output power is kept

constant).

Flame Propagation Your

engine only has a limited amount of time to

burn all the fuel in the combustion chamber

before Citi s swept out to the exhaust.

Without GF2™, fuel is ignited from only one

point in the chamber. A red flame burns from

the top down to the piston head.

GF2™contains compounds that act as flame

initiators. Because of this, the flame in

your engine’s combustion chamber isn’t

propagating only from top to bottom. It’s

also propagating from all of the

GF2™molecules in the fuel. More of the fuel

in the chamber will be burned on each stroke

and less will be wasted in the exhaust.

Pressure Measurements

Sensors inside laboratory engines have shown

that GF2™changes the pressure cycle inside

the combustion chamber. Since the average

pressure is greater inside the chamber, the

piston will receive more force driving it

down. Since the piston is being driven down

faster, more output power will be delivered

to the crankshaft resulting in efficiency

improvements.

Q. Can GF2™ be used by the

shipping industry for heavy fuels such as No

6 diesel fuel (Bunker fuel) A. GF2™ is ideal

for use in shipping industry.

The treatment ratio is:

1:5,000 after use over 1,000 hours the

treatment ratio can be extended 1:7,000 1

gallon of GF2™ will treat 5000 gallons. 1

liter of GF2™ will treat 5000 liters After

1,000 hours 1 gallon of GF2™ to 7,000

gallons bunker fuel. 1 liter of GF2™will

treat 7,000 liters fuel.

As a Combustion Catalyst

GF2™ is a burn rate modifier. Due to its

organometallic compounds, it lowers the

initial combustion point temperature, burns

the lower end BTU’s, and allows a longer

resonance burn time with fewer emissions.

Sulfur Content. Bunker fuel

is exceptionally high in sulfur. GF2

stabilizes the sulfur molecules reducing the

sulfur emissions of SO2 and SO3 about 10% on

average. The remaining sulfer passes through

as particulate matter. SO2 and SO3 form gas

that when released into the atmosphere

combines with water during the condensation

process and forms acid rain.

Polymerization Retardant

Bunker fuel has a longer molecular chain;

almost 3 times longer than diesel fuel. This

means it is more difficult for the longer

molecule to get enough oxygen for a complete

efficient burn. The polymerization retardant

in GF2™Fuel Enhancer will delay the process

of the fuel returning to crude oil and

creating even longer molecular chains.

Cracked fuels begin to deteriorate

immediately after they are refined. As fuel

ages in storage, it re-polymerizes, forming

microscopic particles that score

fuel-metering injectors. As

re-polymerization continues, the molecular

chains become longer and longer, forming

large agglomerates (macroscopic sludge).

Eventually, the fuel may become un-pumpable

and even noncombustible in some cases.

GF2™keeps these carbon

chains from combining, keeping the fuel

stable and eliminating it from returning to

its crude state. Less sludge means more

available BTU’s and more horsepower to the

drive and less manpower required to clean

out the sludge in the holding tanks.

GF2™disperses existing

macroscopic sludge, retards further

polymerization, and permits fuel to be

combusted efficiently with fewer emissions.

GF2™Fuel Enhancer Reduces

engine carbon build up. Reduces engine wear

from carbon build up Reduces

de-carbonization maintenance. Significantly

extends the life of pistons, liners,

injectors, and valve train components etc.

Engine oil lasts longer due to less carbon

in the oil sump/pan. Engines last longer due

to less wear caused by carbon particles in

the oil. Contains Water Demulsifier and

Detergents

Bunker fuel contains

approximately 2% water. GF2™removes water

from the fuel. It also helps eliminate

sludge, and solids from forming and

collecting in the fuel tank and fuel lines.

It increases the life of filters, injectors,

and fuel pumps caused by the above problems.

The demulsifier and detergents will separate

the water and reduce the solid particles in

the fuel. GF2™will help maintain a clean

fuel system, free from water, sludge, and

corrosion.

Reduces Engine Carbonization

Reduces engine carbon build up. Reduces

engine wear from carbon build up Reduces

de‐carbonization maintenance. Significantly

extends the life of pistons, liners,

injectors, and valve train components etc.

Engine oil lasts longer due to less carbon

in the oil sump/pan. Engines last longer due

to less wear caused by carbon particles in

the oil.

1) FUEL STABILITY a)

Removes water from fuel b) Eliminates

existing solids in fuel c) Prevents

polymerization d) Stabilizes fuel in tanks

for many years allowing for the bulk

purchase of fuels when they are inexpensive.

2) FUEL ECONOMY a)

Increases available BTU’s per pound of fuel

@ minimum 3.5% b) Improves fuel economy

and/or horsepower c) Dramatic reduction in

fuel sludge d) Keeps oil cleaner e)

Lubricates fuel system

3) REDUCED MAINTENANCE

COSTS a) Longer life for pistons and

rings (B&W MAN – 12,000 hrs. to 18,000 hrs.)

b) Reduce hard carbon deposits 60% to 90% c)

Dramatic reduction of tank cleaning from

fuel sludge (saves manpower hours) d)

Prevents fuel tank corrosion e) Reduces

combustion system wear f) Prevents catalytic

oxidation 4) ADDITIONAL BENEFITS FOR

“INTERNAL COMBUSTION ENGINES” a) Reduces

vanadium, sulfur, and sodium deposits in the

combustion chamber and exhaust spaces

(valves, turbochargers) b) Reduces or

eliminates need to water wash turbocharger

gas side c) Dispenses existing macroscopic

sludge and stops further re polymerization

d) Helps eliminate filter plugging e)

Extends engine life c) Reduces soot, smoke,

and particulate emissions d) Prevents the

conversion of sulfur to SO2 and SO3.

Can GF2™Fuel Enhancer be

used in Power Generators to make

Electricity?

Yes. Some Power Generating stations use

engines and heavy fuels similar to the

shipping industry. See explanation on how

Can GF2™is used in the shipping industry.

Can GF2™Fuel Enhancer be

used in Open Flame Boilers?

Yes. The following is a synopsis of a test

done at Grupo Fertinal in Mexico. (Full

report on file) It was determined that a

fuel consumption and emissions reduction

analysis should be conducted on two (2), 100

ton-per-hour steam plants utilized for the

production of commercial fertilizers. The

test units selected for this procedure were

unit CA-001, a Babcock and Wilcox, 100

ton-per-hour boiler, and CA-003, a 100

ton-per-hour Rey boiler. CA-001 was

operating at roughly 56.22% efficiency at

baseline, while CA-003 was operating at

about 18.82% efficiency.

The data showed that the

average improvement in fuel consumption, for

the test burner evaluated was 4.6% during

dynamic testing, using the CMB test

procedure and 3.9% using in house volumetric

fuel consumption flow meters.

The treated burner also

demonstrated a large percentage reduction in

soot particulates in the range of 27% and

reductions in harmful exhaust related carbon

fractions. Carbon dioxide reductions, based

upon the measured reduction in fuel

consumption, are also substantial.

Steam production was also

increased by 2.5% in CA-001. Prior to

cleaning, Fertinal employees reported an

absolute efficiency increase of 4.18%

(18.82% to 23%) in CA-003. When applied to

steam generation in tons-per-hour, this

represents an increase in steam production

of close to 20%.

Can GF2™Fuel Enhancer be

used in propane or natural gas?

Yes, GF2™can be used in all hydrocarbon

based fuels. The challenge is the delivery

process to combine the GF2™additive with the

natural gas or propane.

Why do you recommend

GF2™Fuel Enhancer be double dosed for the

first 3 or 4 tank fills on Diesel Fuel?

Engines using diesel fuels naturally begin

to build carbon deposit and varnishes on

pistons, cylinders, valves, injectors,

cylinder heads etc. By using twice the

recommended treatment for the first 3-4 tank

fills GF2™ will burn off all these deposits,

making your engine as clean as when it was

new and operating at its best.

Do I have to double treat

a new engine with just a few

miles/kilometers on it with GF2™?

No it is not necessary to double treat a new

vehicle unless you reside in a place which

has really bad low grade fuel. Just using

the regular treatment of GF2™will keep your

engine clean just like when it was new and

keep the upper engine components, injectors,

valves, fuel pumps etc operating at peak

performance.

What do I do if I get

GF2™Fuel Enhancer on my skin, clothes or

eyes?

First Aid: If you experience difficulty in

breathing, leave the area to obtain fresh

air. If continued difficulty is experienced,

get medical attention immediately. In case

of eye contact flush immediately with plenty

of water for at least 15 minutes and get

medical attention; for skin, wash thoroughly

with soap and water. Remove contaminated

clothing. wash contaminated clothing before

re-use. If ingested do not induce vomiting,

keep warm, get medical attention. Acute

Health Hazards: Eyes – Can cause irritation,

redness, blurred vision and possible

permanent damage. Skin – Prolonged contact

can cause irritation, dermatitis. Ingestion

– Harmful or fatal if swallowed. Can cause

gastrointestinal irritation, nausea,

vomiting and diarrhea. Inhalation – High

concentrations can cause irritation,

dizziness, nauseam fatigue headache and

unconsciousness or asphyxiation. Warning: DO

NOT TAKE INTERNALLY. Prolonged or repeated

overexposure can cause organ damage and an

increased risk of cancer. KEEP OUT OF REACH

OF CHILDREN. For emergency, call your

physician, local poison control center or

local emergency room or call (800) 424-9300,

for other information call (505) 892-9601.

Handling and Storage:

Protect from physical damage. Store in a

cool, dry ventilated area away from acids,

alkalis and open flames. For additional

safety information, refer to the Material

Safety Data Sheet for this product.

Disposal: Place opened,

empty containers in normal refuse for

disposal. Contact your sanitation department

or hazardous waste coordinator for

information concerning disposal of unused

product.

Accidental release measures:

Clean spill with absorbent materials.

Eliminate ignition sources. Use full face

NIOSH approved organic respirator if TWA/TLV

limits are exceeded. Avoid runoff into storm

sewers and ditches which lead to waterways.

Is GF2™Fuel Enhancer

hazardous and toxic?

Yes GF2™is hazardous and toxic. Read

instructions on use carefully. However when

used properly in your engine it is rendered

harmless.

Why does the GF2™Fuel

Enhancer bottle state it does not meet EPA

2007 sulfur standards. As a stand alone

product on the shelf it does not meet the

2007 low sulfur standards. But when diluted

in fuel the sulfur content is negible and

more than meets the EPA 2007 low sulfur

standards.

How do I calculate the

correct amount of GF2™Fuel Enhancer to use

in my vehicle. 1 oz (29.57ml) of GF2™will

treat 80 gallons (302 liters) of fuel either

gasoline or diesel. 10ml will treat 20

gallons (75.60 liters) 20ml’s will treat 40

gallons (151 liters).

How do I use the GF2™Fuel

Enhancer bottle?

Watch our video in the HHG University.

The GF2™bottle is simple to

use. Make sure the cap is on tight. Turn the

bottle upside down and fill the reservoir

until it’s full. Turn the bottle until the

scale and window is facing you and you can

see the liquid in the window.

Let’s say you only want

10ml’s of additive. You will notice 2 scales

one on either side of the window where the

reservoir is. The scale on the right hand

side indicates the measurement in ml. The

scale on the left hand side is the measuring

scale. The scale on the left hand side

determines the amount of fluid which will

show up in the reservoir on the right hand

side scale.

With the scale and window

facing you, tip the top of the bottle away

from you until the fluid reaches the lowest

scale on the left hand side of the window

for 10ml. Once the liquid in the reservoir

reaches the lowest mark of the scale on the

left hand side of the window (10ml) then

just tilt the bottle a little further until

you gauge approximately 10 ml. When you set

the bottle up vertically you will have the

correct amount of additive in the reservoir

and on the right hand side where it should

show 10ml. For larger amounts of additive

use the next scale above.

THE EFFECTIVENESS OF

GF2™Fuel Enhancer

Carbon Mass Balance

testing can be used to evaluate the

effectiveness of GF2™. The Carbon Mass

Balance test measures carbon leaving the

engine in the form of exhaust. The only

source of carbon the engine has is its

fuel. Mass cannot be created or

destroyed; so the amount of fuel

entering the engine can be determined.

If the amount of fuel used is reduced

under a given load, the effectiveness of

a fuel treatment can be measured. This

procedure is ideal for determining

whether the addition of a fuel treatment

has any effect on fuel efficiency and

exhaust emissions that pollute the

environment.

Carbon Mass Balance Test

results of GF2™Fuel Enhancer shows that

harmful emissions are significantly

lower.

GF2™’s interaction with

fuel can be explained using a chemical

formula.The basic principles behind the

benefits and catalytic effects of

GF2™are easy to understand. Today’s

engines leave some amount of fuel

unburned on each piston stroke.

GF2™makes it easier for your engine to

burn more of the fuel in the cylinder.

Since more of the fuel is being burned,

more power is being generated. Since

less of the fuel is being wasted, you

will have fewer emissions and better

economy which saves money.

Chemistry

An engine converts fuel

into energy by the following chemical

processes:

CxHy + O2 → ( CO2 + H2O

) + ( CO + HC + C ) + ΔH

The ΔH is known in

chemistry as enthalpy and represents the

energy created from the thermodynamic

process taking place inside an engine.

The CxHy represents the fuel, for

example gasoline is C8H18 and diesel is

C12H26. The CO2, H2O, CO, HC, and C on

the right side of the arrow represent

products that are released in the engine

exhaust.

There are no exothermic

(i.e. energy producing) reactions that

could yield more energy out of the CO2

or H2O, so we’ve grouped those

components together in the equation

above. However, there are exothermic

reactions that can extract additional

energy from the second group: the CO,

HC, and C.

When GF2™is introduced

into the engine; it acts as a catalyst

and lowers the activation energy needed

to further break down the unburned

products in the above reactions.

Specifically, when GF2™is used the

following additional chemical processes

take place in the engine:

CO + O2 → CO2 + ΔH

HC + O2 → CO2 + H2O + ΔH

C + O2 → CO2 + ΔH

The ΔH’s in the three

above equations are how GF2™increases

your engine’s output. These ΔH’s add to

the ΔH produced by the engine’s standard

process to deliver more output energy

from the engine. This extra energy can

be used to either increase engine output

power (if the amount of fuel input is

kept constant) or reduce the engine’s

fuel intake (if the amount of output

power is kept constant).

Customer Highlight

Because of the data

available and results monitored over

a period of 15 years including the

awards granted, one speciGic company

will be used to show the success of

GF2 fuel treatment in that company’s

equipment.

We will outline four

primary areas of benefit.

• Operational:

• Maintenance:

• Economic:

• Environmental: Significantly

Reduced Emissions.

Fuel economy and

engine efficiency.

Reduced costs and

extended engine and component

lifespan. Overall net savings

directly impacting bottom line

profits.

These categories

have been evaluated using one of the

largest and most successful mining

contractors in the world PT

Pamapersada (PAMA) based in

Jakarta, Indonesia.

PAMA’s

founder and former President Mr.

Sudiarso Prasetio, became

lifelong friends with HHG’s supplier

whose products have contributed to

PAMA’s success and profitability

with annual double digit growth

Gigures since they began Girst using

the GF2 Formulation.

Operational

GF2TM is unique

compared to other fuel treatments on

the market. Instead of having to use

several one off treatments, GF2TM is

completely self-contained with

everything the fuel needs, to allow

the engine to run smoothly and

efGiciently for a very long time

extending the life of expensive

components such as injectors, pumps,

liners, valve system etc. It is

highly concentrated containing the

following essential components below

but without the Gillers other

manufacturers use making it the most

cost effective fuel treatment on the

market today.

Normal Treatment

ratio is 1:10,000, 1 gallon treats

10,000 gallons, or 1 liter treats

10,000 liters. This is the original

product and not a copy.

In Ship and Power

Generation Engines using Bunker

Fuels the Treatment ratio is 1:5,000

for 1st 800 hours of use then

1:7,500 for regular usage.

1.Combustion

Catalyst made up of complex

organometallic compounds including

ferrocene which helps lower the

initial burn rate of the fuel in the

cylinder, allowing more time for the

fuel closest to the piston to burn

more completely. This also helps

reduce sulfur by products. The

engine has a limited amount of time

to burn all of the fuel in the

combustion chamber before it is

swept out to the exhaust.

Without GF2TM, fuel

is ignited from only one point in

the chamber. Normally the Glame

burns from the top down to the

piston head.

With GF2TM multiple

Glames occur in your engine's

combustion chamber propagating from

all of the GF2TM molecules in the

fuel. More of the fuel in the

chamber is burned on each stroke and

less is wasted in the exhaust. This

allows more of the BTU’s in the fuel

to be released and used in the form

of energy to deliver more power to

the transmission providing better

overall fuel economy, using less DEF

Gluid and saving on regen systems

and catalytic convertors. If unburnt

fuel is entering the exhaust system

that means you lost money.

2.Cetane is

vastly improved in diesel engines

with the use of GF2TM allowing for

most of the diesel fuel to be

consumed in the cylinder, increasing

horsepower and performance and

reducing smoke/soot.

3.Octane: By

adding GF2TM to the lowest grade of

gasoline fuel, it will provide the

performance of the higher grade

fuels but with more BTU’s available

for the power band. High performance

engines can use the lowest grade

gasoline fuels with GF2TM and not be

subject to pre-ignition knock which

previously required them to use the

more expensive gasoline fuels. It

all has to do with getting more

oxygen molecules around the fuel.

4.Lubrication

additive, recent legislative

changes to reduce sulfur content in

fuels and eliminate all lead, have

meant a decrease in the inherent

lubricity of diesel fuel as well as

gasoline (petrol). Experts estimate

that as much as 50 percent of

today’s ULSD (ultra-low sulfur

diesel) pool will need a lubricity

improver to meet engine

manufacturer’s speciGications and

that up to 75 percent of the diesel

pool could require treatment as

reGiners convert to ULSD production

in 2006 and beyond.

GF2TM includes a

synthetic lubricity agent that

addresses the Engine Manufacturers

Association (EMA) preferred diesel

fuel lubricity speciGication, the

FQP-1.

The ASTM D-6079

diesel lubricity speciGication test

balances input from engine makers,

standards ofGicials, and fuels

producers. It says that a “wear

scar” no larger than 520 μm

(microns) in diameter should result

from a standardized wear test. The

lubricity agent in GF2TM, when

analyzed under the ASTM D-6079 test

speciGications produced a wear scar

of less than 440 μm, far exceeding

the requirements for lubricity

speciGications required by engine

manufacturers.

5.Water

Demulsifier which separates

water from fuel making it more

efGicient in the combustion process,

eliminating harmful acids which are

by products of the combustion

process in water contaminated fuels

and which cause pitting and

component failure.

6.Polymerization

Retardants which stop the fuel

from breaking down and returning to

its natural state as crude oil which

is what fuels begin to do typically

30 days after being “cracked” at the

reGinery.

This polymerization

process starts to form

submicron-sized particles. As the

process continues, particles become

larger and eventually agglomerate,

forming macroscopic sludge. These

particles can score injectors and

eventually plug Gilters and the very

small openings in the injector’s

nozzles and over long periods of

time render the fuel un-pumpable.

Equipment left for long periods of

time without being used such as

seasonal equipment like boats, lawn

movers, tractors, off road vehicles,

trucks etc. become very hard to

start because of this polymerization

process.

GF2TM disperses

existing macroscopic sludge and

retards further polymerization,

permitting the fuel to Glow and burn

more efGiciently making it ideal for

use in heavy fuels such as No 6

diesel or bunker fuel, which is used

in ships and power generators.

GF2TM is perfect for

long term fuel storage especially

emergency generators which are vital

and need to start when utility power

goes down. Companies can purchase

large quantities of fuel when the

price has dropped and can store that

fuel for very long periods of time

keeping it fresh and alive with the

use of GF2TM.

7.Oxidation

stabilizer. All fuels are

subject to oxidation. Oxidation

creates in-soluble by products which

cause injector deposits like a

varnish. These deposits can slow

response or cause sticking of moving

internal parts and lead to injector

failure. GF2TM contains a dispersant

that stabilizes fuels, preventing

oxidation.

8.Corrosion

inhibitors. Many parts of an

engine are made up of ferrous metal

components, aluminum and plastics.

Many fuels today contain Ethanol

which is alcohol and highly

corrosive to fuel lines and engine

components. GF2TM contains a

corrosion inhibitor in order to

mitigate corrosion in tanks, engines

and fuel lines and a detergent to

help keep engines, fuel lines,

Gilters, pumps and injectors clean.

This will result in increased

efGiciency, less breakdowns and less

maintenance for your equipment.

9.Detergents

which keep the fuel system

components clean and within original

design tolerances for precise fuel

delivery to the combustion chamber.

All of the above

provide better running equipment,

less breakdowns, more profits and a

cleaner environment, all in one

simple, effective, treatment.

Maintenance

When PAMA

Girst began using the GF2TM

formulation their engines were being

overhauled at 12,000 hour intervals

on average. Using the GF2TM formula

the engine life was extended to over

18,000 hours of operation as there

was much less wear in cylinders,

valves, and fuel delivery systems

especially injectors and fuel pumps

and this required fewer personnel

for repairs.

(Typical costs of

overhauling these engines are

$250,000 - $500,000) They have

reduced their maintenance budget by

40%.

This is unheard of

in an industry which is the harshest

environment for equipment on the

planet.

Economic

Q. How

effective is GF2 in providing a

Return on Investment for heavy

industry?

A. The GF2

formulation treats over 300 million

gallons of diesel fuel (over 1

billion liters) for PAMA each

year with the GF2TM formula. This

saves PAMA in excess of $50

million dollars per year in fuel

consumption alone.

The GF2TM formula

provides PAMA with up to 8%

fuel savings in addition to what

they save not having to purchase

equipment replacement parts.

By using the GF2

formula , PAMA's return on

investment (ROI) with this fuel

treatment is over 600% providing a

huge proGit margin for the company.

GF2TM is the most

cost effective Fuel treatment for

all commercial equipment including

the general public’s personal

vehicles. Remember PAMA, is

one of the largest mining

contractors in the entire world and

the largest purchaser and user of

Komatsu mining equipment as well as

the largest purchaser and user of

Volvo articulating trucks worldwide.

PAMA annual

revenue is $4 Billion dollars and

annual proGit is $900 million.

PAMA attributes over $300

million of those profits to GF2TM

formulation

Environment

Q. Is GF2TM

proven to reduce pollution?

A. Yes! Once

again let’s use PT Pamapersada (PAMA)

as the example.

PAMA received

ISO 14064-2 award which is an

International Standard related to

the reduction of Greenhouse Gas

Emissions, on March 10 2014. They

received this award as a direct

result of using GF2TM . By using

this product they eliminated

516,912.2 tons of CO2 emissions

in 2012 compared to 2011. That is

the equivalent of removing 116,000

full size automobiles off the road

in one year.

PAMA is the

1st and only mining operation

worldwide and the only company in

Indonesia, to have won such a

prestigious award all thanks to the

GF2TM formula .

Carbon Credits.

PAMA continues to sell their

carbon credits for considerable

proGit each year.

The result of

PAMA’s use of the GF2TM formula

is the people of Indonesia have a

cleaner environment in which to live

and the huge economic gains that a

large company such as PAMA

provides the country.